Steering calibration

As part of our commitment to delivering exceptional experiences, each participant will receive a finely assembled RC car. Our dedicated assembly line has crafted these cars with precision, ensuring that they’re ready for action right out of the box.

However, like all masterpieces, there might be minor variations in the steering calibration due to the manual assembly process. This isn’t a flaw, but a proof to the individual attention each car has received. For instance, while you might set the car to turn at 15 degrees, it could turn at, say, 17 degrees in reality.

The Solution

To enhance your experience and ensure consistent performance, we’ve deduced a mathematical solution to address these minor calibration variations…

Required Tools:

To accurately measure the steering angle of the cars, it’s essential to have the right tools on hand and to follow the steps below:

Ruler: For precise measurements.

- Two markers:

One for the initial position of the car (when it’s at 0).

One for the final position of the car (when it reaches the desired point).

Measuring Procedure:

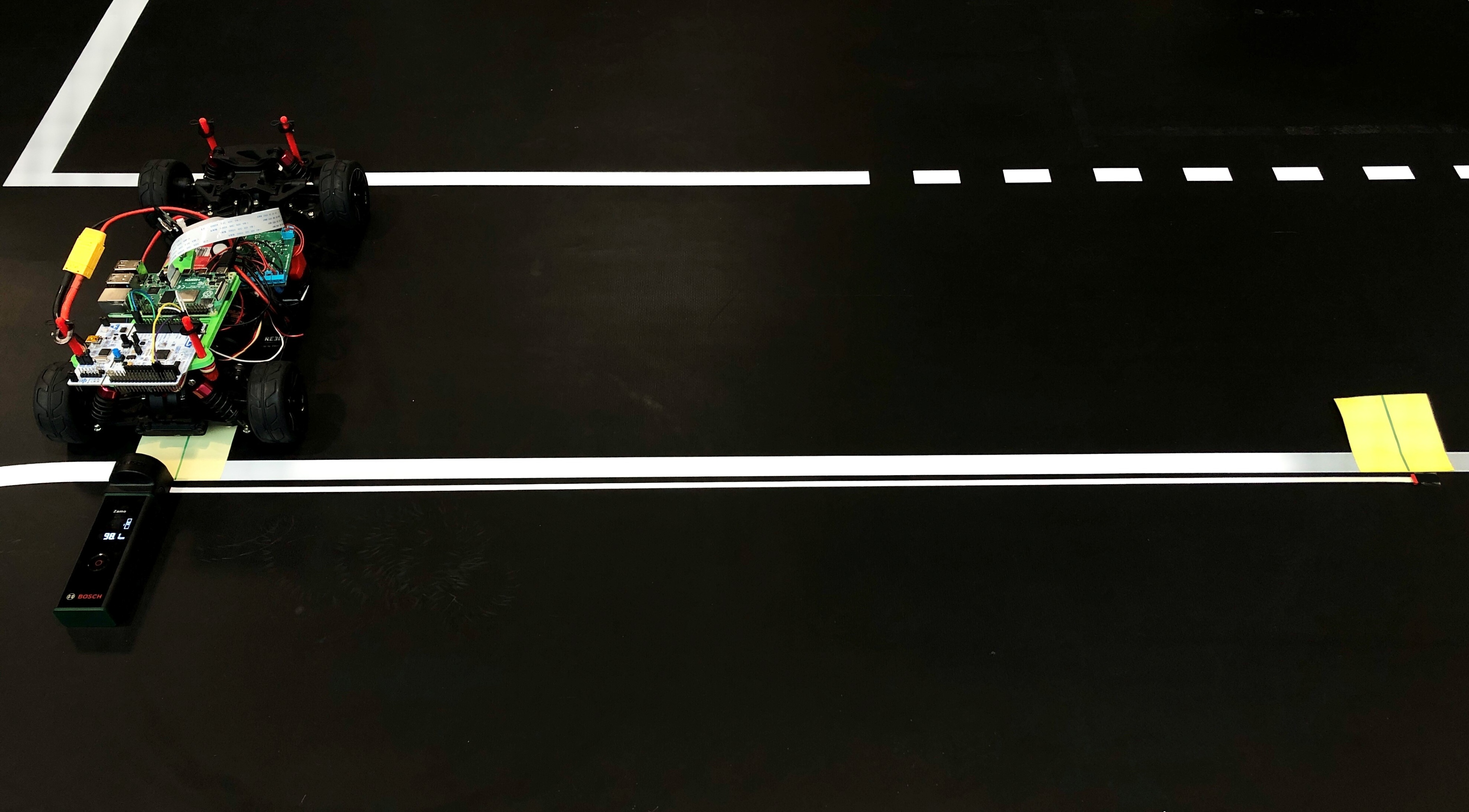

Below, you will find a figure illustrating the steps and the procedure required for the measurement process.

Place the first marker underneath the midpoint of the rear axle when the car is at point 0.

Move the car to the desired point or its steering limit.

Place the second marker underneath the midpoint of the rear axle at the final position.

Ensure that the starting (0 point) and final positions are on the same straight line, essentially forming a semicircle.

Use the ruler to measure the distance between the two markers.

This distance will represent the diameter of the turning circle of the RC car. Use this value in the formula below.

\[\theta = \arctan\left(\frac{L}{R}\right)\]\[\text{where:}\]\[L = \text{wheelbase (260 mm = 0.26 m)}\]\[R = \frac{\text{measured diameter}}{2} \text{[m]}\]

By following these steps, you’ll obtain an accurate measurement of the car’s steering angle in radians, you need to convert the value to degrees. Ensure to perform these measurements in a stable environment without disturbances for the most accurate results.

Fine tune the steering system

To fine-tune the steering calibration of your RC car, we focus on two main parameters:

- 1. zero_default parameter

In situations where the steering system exhibits significant deviations in a particular direction during testing, this parameter needs to be updated. For instance, if you test for values (15, -15) and obtain results (14, -16), adjustments are required.

- 2. step_value parameter

In situations where the steering system’s response is either below or above the expected range during testing, this parameter should be adjusted. For instance, when testing for values (15, -15) and obtaining results such as (14, -14) or (16, -16), adjustments are required.

Adjusting the zero_default parameter

Adjustment to zero_default (ΔDC): This is the product of the discrepancy and the step value. It helps us determine how much we need to adjust our zero_default parameter to match our desired turning angles.

Average Discrepancy (D): This represents the average difference between the desired and actual turning angles of the car, in both positive and negative directions.. To calculate the average discrepancy you can use the formula below:

\[D = \frac{(dpa - apa) + (dna - ana)}{2}\]\[\text{where:}\]\[dpa = \text{desired positive angle}\]\[apa = \text{actual positive angle}\]\[dna = \text{desired negative angle}\]\[ana = \text{actual negative angle}\]Desired Positive Angle (dpa): The angle you want the RC car to turn in a positive direction.

Actual Positive Angle (apa): The actual angle to which the RC car turns in a positive direction.

Desired Negative Angle (dna): The angle you want the RC car to turn in a negative direction.

Actual Negative Angle (ana): The actual angle to which the RC car turns in a negative direction.

Step Value (SV): This value denotes the actual measure or increment by which the steering system operates.

Using the formulas above, you can calculate the ΔDC value, which will guide you on adjusting the zero_default value of the steering system. By doing this, you’ll ensure that when you command your RC car to turn at a specific angle, it does so accurately on both sides!

After determining the ΔDC value using the discrepancy (D) and the actual step value (SV), you can adjust the zero_default value of the steering system with the following formula:

new zero default is the updated value to be set for the steering system.

current zero is the present zero_default value of the steering system.

ΔDC is the value we calculated earlier, which represents the adjustment needed.

Understanding the Plus-Minus Sign

When adjusting the zero_default value, it’s important to understand the direction in which to make the adjustment:

If the deviation is greater in the negative direction, you should increase the zero_default value. For example, if you test the steering direction for the value set (15, -15) and you get results like (15.5, -16.5), then you should increase the zero_default value.

Conversely:

If the deviation is greater in the positive direction, decrease the zero_default.

This new zero default value will ensure that the RC car steers accurately according to the desired angle, taking into account any discrepancies found in the actual turning angles.

Adjusting the Step Value parameter

To fine-tune the steering mechanism’s responsiveness, users can modify the step value. The formula for this is:

ΔSV can be calculated as:

Understanding the Plus-Minus Sign

When adjusting the step_value value, it’s important to understand the direction in which to make the adjustment:

If the steering angle obtained is smaller than the desired one, then you need to increase the step value. For instance, if when testing the direction for a value of 15 you obtain 14, then you should increase the step value.

Conversely:

If the steering angle obtained is greater than the desired one, then you need to decrease the step value. For instance, if when testing the direction for a value of 15 you obtain 16, then you should decrease the step value.

Update predefined values for Steering

Operational example: After conducting tests for the values (16, -16) and determining the appropriate step_value and zero_default values to achieve the desired steering angles, you must update them in the following variables:

const float steeringValueP[2] = {15.0, 20.0};

const float steeringValueN[2] = {-15.0, -20.0};

const float stepValues[2] = {0.0008594, 0.000951570};

const float zeroDefaultValues[2] = {0.07714891, 0.07672070};

Embedded_Platform\include\drivers\steeringmotor.hpp

You must pay attention to the position within the array of the values. If 16 has an index of 2 in the positive values array, it should have the same index in the negative values array. The same applies to the step_value and zero_default values.

Utilize this guidance and the formulas provided to ensure that the steering mechanism is adjusted appropriately for optimal performance. Remember, accurate steering calibration is crucial for optimal performance, so ensure you follow the above steps carefully.